A packaging press check is a critical step in ensuring your design comes to life as intended. It’s your opportunity to review the final printed product and make sure it aligns with your brand’s standards and expectations. However, press checks can be fast-paced and high-pressure, so preparation is key.

Here are five essential tips to help you navigate the press check process successfully and achieve the best possible results.

1. Review Final Proofs Thoroughly

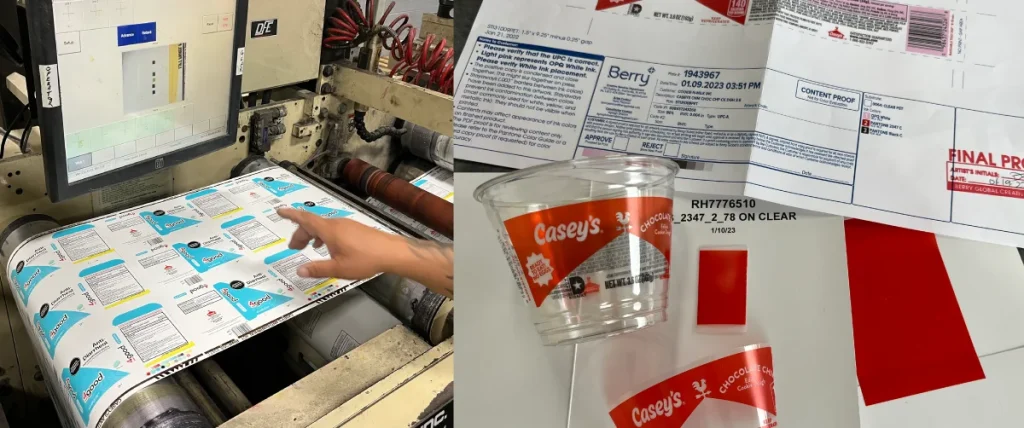

When your project is on press, it’s not the time to make last-minute content changes. To avoid costly delays, ensure you’ve carefully reviewed all printer-provided PDFs, physical color proofs, and ink drawdowns beforehand. Double-check every detail, including graphics, legal and regulatory content, image quality, and color accuracy. Ask your printer how the substrate might influence the final appearance, such as color or glossiness. Address any concerns early and have a fully approved proof before the press check begins.

2. Bring Color Standards

Your brand’s colors are integral to its identity, so it’s essential to bring your own color standards to the press check. This might include Pantone swatches, previously printed samples, or other approved references. These standards ensure that the colors coming off the press match your brand’s exact specifications, giving you peace of mind that your packaging will look consistent and on-brand.

3. Inspect Print Quality

During the press check, closely examine the print samples for sharpness, clarity, and color consistency across the sheet or imprint. While the color might look great in one area, it could appear weaker in another, so inspect all sections thoroughly. Be on the lookout for issues like smudges, streaks, or other defects that could detract from the finished product’s quality.

4. Check Registration and Alignment

Misalignments, even minor ones, can impact the readability and overall appearance of your packaging. Carefully inspect the graphics and text for proper registration and alignment. If the print sheet includes multiple impressions, check each one for consistency. Keep an eye out for areas where one side of the sheet might be perfectly aligned while the other side is slightly off, and communicate any issues with the printer.

5. Communicate with the Printer

A successful press check relies on open communication with the press team. If you spot any concerns, speak up—they’re the experts on their equipment and can often provide solutions or suggestions to achieve your desired outcome. Understand that certain changes may require adjustments to print plates or other time-consuming processes, so prioritize what’s most critical. A collaborative approach helps ensure the best possible results without unnecessary delays.

A press check is your last chance to ensure your packaging design meets expectations, so preparation is essential. At Lundmark, we’ve guided countless clients through the packaging press check process, ensuring their designs translate seamlessly from concept to production. If you’re ready to take your packaging to the next level, our team is here to help. Contact us today to discuss your next project!